Cricket

There’s been an ongoing debate in international cricket about making the Dukes cricket ball the mandatory Test ball for matches across the globe.

Currently, the red Dukes cricket ball is used by England, West Indies and Ireland for Test matches. India tends to prefer the locally-manufactured SG cricket ball while the other Test-playing nations use the Australian-manufactured Kookaburra ball.

But as far as player performance is concerned, the Dukes ball is concerned superior since it retains its shape over several hours of playing. Seamers tend to get a lot of sideways movement with the ball once they have worked on the shine, and batsmen have also reported getting a good feel of the ball through the bat when they strike it.

The most important thing about the Dukes ball is that it is highly durable due to a unique format of hand stitching and multiple layers of seams. The Dukes ball manufactured by the British Cricket Balls Ltd company holds its shine and seam for reasonably long, allowing bowlers to produce impressive results from it even 40 or 50 overs into using it.

So how is a Dukes ball made to last longer than other cricket balls and give players the best in performance?

Unique leather

Dilip Jajodia, the owner of the British Cricket Balls company, says it starts with the leather.

The East London-based company has always imported its leather for cricket balls from a particular tannery in Scotland. The company believes the leather produced at this specific tannery is the best available for the manufacture of cricket balls.

The thickness of this leather is between 4mm and 4.5mm. In contrast, the leather used in the SG ball in India is about 2mm to 3mm thick.

Once this leather is received, the Dukes ball makers dry and compress the leather down to a thickness of 3.5mm; the minimum standard for a Dukes ball.

Furthermore, while SG and Kookaburra use two pieces of leather for their white balls (they use four pieces for Test balls), a Dukes ball is always made using four pieces of hand-stitched leather. Also, the Dukes manufacturers are cautious about maintaining an even thickness with the parts of leather.

“All the four parts of a ball come from a consecutive piece of leather from the same cow. That’s how we control the thickness of the four pieces of leather which are being used in a single ball. We make sure that the minimum thickness is 3.5mm,” said Jajodia, a former bowler from India who moved to the United Kingdom in 1962.

Another aspect of maintaining the quality of the ball is the cork used under the leather. The chunk of cork – which comprises the hard core of a Dukes ball – is machine made. The rubber used in the cork is imported from Malaysia.

Polishing and stitching

The red Dukes balls used in Test matches are known to produce amazing results and help peak player performances. The style of hand stitching and the unique polish applied to the leather are credited for these results.

After being treated, the leather is polished with a synthetic grease. This protects the ball from wet conditions so it won’t soak up too much water.

In the case of the red Dukes ball, the more the leather soaks the grease, the better the ball becomes. That’s why the red Dukes ball is darker and shinier than other red cricket balls. This deep polish and shine directly contribute to the amount of swing a bowler can extract from the ball.

However, in the case of the pink ball used in day-night cricket, the amount of grease used is limited since it affects the visibility of the ball in dim-lit conditions. This is also the reason the pink Dukes ball loses its shine early.

After the grease treatment, the ball is assembled through a unique format of hand stitching. Each ball is stitched by an artisan who creates six rows of thread going backwards, forwards and underneath.

The persons who stitch the ball dedicate at least one hour to each ball and produce no more than eight balls in a day. The entire process is done by hand, without the use of any machines or measuring tools. These artisans are often second-generation employees of the company who were trained by their relatives that previously performed the task.

Unique to the seam of the Dukes ball is that it has six rows of thread as opposed to the common four rows produced by machine-made balls elsewhere. That’s why the seam of a Dukes ball is much more pronounced, and fast bowlers always find it easy to grip.

Jajodia believes that the six rows of thread hand stitched in by Dukes manufacturers help the ball become tighter and retain better shape to help bowlers. He says the hardness and firm seam make the ball move more, both in the air and off the pitch.

Once the final threading is done, a final polish is applied to the ball to make it shine more. This outer layer of shine is what players generally work on with sweat and saliva to wear off one side of the ball and produce more swing.

Rigid testing

Once the ball is ready for use, it goes through three stern tests before it is declared ready for use in a match.

First, the shape of the ball is checked. The ball should be perfectly round, so it does not affect the player’s performances. The ball is passed through a metal sheet with three holes to make sure it is the right shape and size. Umpires on field use a similar piece of equipment to check the shape of the ball during matches.

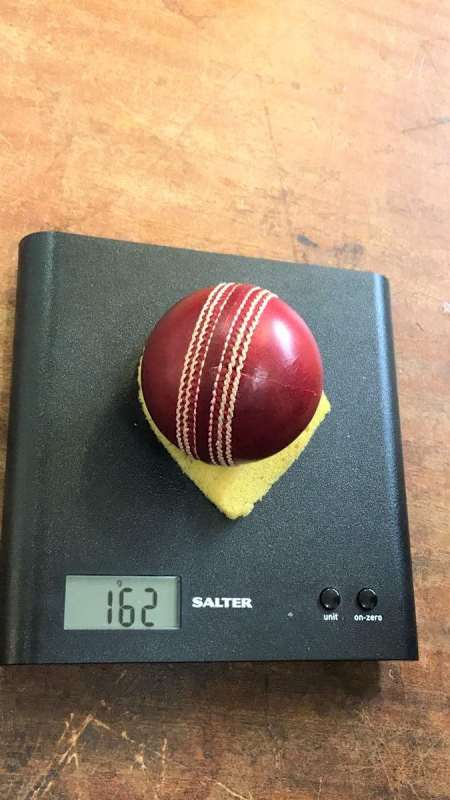

The second test relates to the weight of the ball. Each ball must weigh between 156 grams and 163 grams to be used in a match.

The third test is to check the bounce of the ball. The ball is dropped from a height of six feet and must rebound to within a certain range to be cleared for the final approval.

Finally, Jajodia checks each approved ball himself and recommends which balls should be used for an upcoming match.

A single Dukes ball takes at least three-and-a-half hours of dedicated human labour to be prepared. But at the end, each ball is perfectly suited to help players provide their best performance